What is Solar Cable / Photovoltaic Cable

Solar cables, also known as photovoltaic (PV) cables, are a critical component of solar energy systems, facilitating the efficient transmission of electrical power generated by solar panels. These specialized cables are designed to meet the unique demands of solar installations, ensuring the safe and reliable distribution of clean energy. As the world increasingly embraces solar power as a sustainable energy source, understanding the importance and features of solar cables is essential.

Key Features and Benefits

UV and Weather Resistance:

Solar cables are exposed to outdoor conditions, and as such, they are engineered to withstand extreme weather conditions, including UV radiation, heat, cold, and moisture. Their robust construction ensures long-term durability.

High Temperature Tolerance:

Solar cables are designed to handle high temperatures generated by solar panels under direct sunlight. This feature prevents cable degradation and ensures efficient power transmission.

Flexibility:

Solar cables are highly flexible, making them easy to install even in challenging terrain or irregular layouts. Their flexibility simplifies the installation process and reduces the need for complex cable routing.

Flame Retardancy:

Safety is paramount in solar installations. Solar cables are often flame-retardant, reducing the risk of fire hazards and ensuring the safety of both the installation and the surrounding environment.

Low Smoke Emission:

In the event of a fire, solar cables typically produce minimal smoke, contributing to safer evacuation conditions and reduced damage to property.

Send e-mail to sales@xinfengcable.com to get quotation and more technical sheet.

Applications:

Solar cables are widely used in various solar energy applications, including:

Solar Photovoltaic Systems: Solar cables connect solar panels to inverters and other components within solar PV systems. They play a pivotal role in transmitting DC power from the panels to the inverters, where it is converted to AC power for use in homes, businesses, and the grid.

Solar Farms: Large-scale solar farms utilize solar cables to interconnect arrays of solar panels, ensuring efficient power collection and distribution.

Residential Solar Installations: Solar cables are essential in residential solar systems, connecting rooftop solar panels to the rest of the electrical infrastructure within the home.

Commercial and Industrial Solar Projects: Solar cables support the expansion of solar energy in commercial and industrial settings, contributing to sustainable power generation for businesses.

In a world increasingly focused on renewable energy solutions, solar cables play a crucial role in harnessing the power of the sun. Their reliability, durability, and safety features make them indispensable components of solar energy systems, enabling a cleaner and more sustainable future for all.

As solar energy continues to grow as a pivotal part of our global energy mix, the significance of solar cables in facilitating this transition cannot be overstated.

Electrical Properties

Rated Voltage U 0/U: AC: 1000V/1000V AC; DC:1500V/1500V ;

Maximum Permitted DC Voltage: 1800V DC (conductor/conductor, non-earthed system, circuit not under load)

Spark Test: 6000 V ac (8400 V dc)

Voltage Withstand: 6500 V ac for 5 min

Thermal Properties

Maximum Voltage: Ambient Temperature: -40℃ ℃~ +90℃

Maximum Temperature At Conductor: 120℃ ℃(20000h) according to IEC/EN 60216-1

Short Circuit Temperature: 200℃/5 sec

Thermal Endurance Test: According to EN 60216-2 (temperature index +120° °C)

High Temperature Pressure Test: According to EN 60811-3-1» Damp-Heat Resistance: According to EN 60068-2-78 with 85% humidity

Mechanical Properties

Minimum Bending Radius: 4×OD (fixed), 5×OD (flexing)

Dynamic Penetration: According to 2 PfG 1169/08.2007 Annex F

Notch Propagation: According to 2 PfG 1169/08.2007 Annex G

Tensile Strength and Elongation Of Insulation And Jacket: According to EN 60811

Anticipated Period Of Use: 25 years

Chemical Properties

Ozone Resistance: According to EN 50396 part 8.1.3 Method B

Weathering-UV Resistance: According to HD 605/A1

Ammoniac resistant

Very good resistance to oils and chemicals

High wear and robust, abrasion resistant

Acid & Alkaline Resistance: According to EN 60811-2-1 (Oxal acid and sodium hydroxide)

EC directives

The cables are conform to the EC directives CE 2006/95/EC (Low voltage directive) and RoHS 2002/95/EC (Restriction of Hazardous Substances)

Fire Performance

Flame retardant according to EN 50265-2-1, IEC 60332-1, VDE 0482-332-1-2, DIN EN 60332-1-2

Low smoke emission according to IEC 61034, EN 50268

Halogen free according to EN 50267-2-1, IEC 60754-1

Low corrosively of gases according to EN 50267-2-2, IEC 60754-2

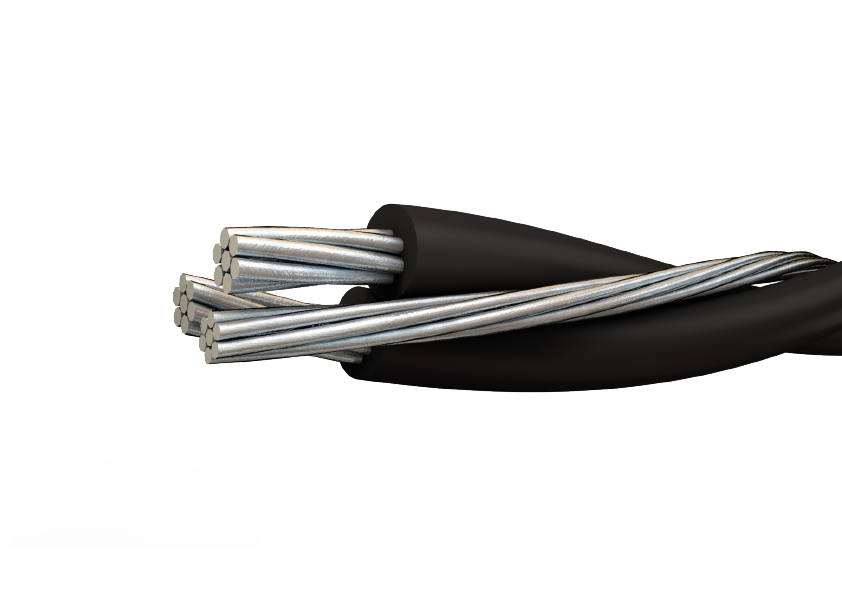

Construction

Conductor: Stranded tinned copper conductor per DIN VDE 0295 and IEC 60228 Class 5.

Insulation: Electron beam cross-linked, halogen free and flame retardant compound.

Sheath: Electron beam cross-linked, halogen free and flame retardant compound, Black or Red.

| No.of cores x Nominal Cross Section No. x mm2 |

Mean Overall Diameter Upper limit mm |

Nominal Weight kg/km |

Minimum insulation resistance 20°C MΩ•km |

Minimum insulation resistance 90°C MΩ•km |

Maximum Conductor DC Resistance 20℃ Ω/km |

Maximum Conductor AC Resistance 90℃ Ω/km |

| 1×1.5 | 5.4 | 36 | 860 | 0.86 | 13.7 | 17.5 |

| 1×2.5 | 5.9 | 46 | 690 | 0.69 | 8.21 | 10.5 |

| 1×4 | 6.6 | 62 | 580 | 0.58 | 5.09 | 6.5 |

| 1×6 | 7.4 | 82 | 500 | 0.5 | 3.39 | 4.32 |

| 1×10 | 8.8 | 125 | 420 | 0.42 | 1.95 | 2.49 |

| 1×16 | 10.1 | 190 | 340 | 0.34 | 1.24 | 1.58 |

| 1×25 | 12.5 | 285 | 340 | 0.34 | 0.795 | 1.013 |

| 1×35 | 14 | 385 | 290 | 0.29 | 0.565 | 0.72 |

| 1×50 | 16.3 | 540 | 270 | 0.27 | 0.393 | 0.501 |

| 1×70 | 18.7 | 740 | 250 | 0.25 | 0.277 | 0.353 |

| 1×95 | 20.8 | 965 | 220 | 0.22 | 0.21 | 0.267 |

| 1×120 | 22.8 | 1210 | 210 | 0.21 | 0.164 | 0.209 |

| 1×150 | 25.5 | 1495 | 210 | 0.21 | 0.132 | 0.168 |

| 1×185 | 28.5 | 1885 | 200 | 0.2 | 0.108 | 0.137 |

| 1×240 | 32.1 | 2395 | 200 | 0.2 | 0.0817 | 0.104 |

| 2×1.5 | 5.4×11.5 | 72 | 860 | 0.86 | 13.7 | 17.5 |

| 2×2.5 | 5.9×12.6 | 97 | 690 | 0.69 | 8.21 | 10.5 |

| 2×4 | 6.6×14.0 | 130 | 580 | 0.58 | 5.09 | 6.5 |

| 2×6 | 7.4×16.4 | 170 | 500 | 0.5 | 3.39 | 4.32 |

| 2×10 | 8.8×19.1 | 265 | 420 | 0.42 | 1.95 | 2.49 |

| 2×16 | 10.1×23.9 | 394 | 340 | 0.34 | 1.24 | 1.58 |

| 2×25 | 12.5×26.3 | 585 | 340 | 0.34 | 0.795 | 1.013 |

| 2×35 | 14.0×29.9 | 789 | 290 | 0.29 | 0.565 | 0.72 |

How to get the manufacturer?

Xinfeng Cable: Your Trusted Professional Solar Cable Manufacturer

As the world embraces solar energy as a sustainable power source, the demand for high-quality solar cables has never been greater. Xinfeng Cable proudly stands as a leading and trusted name in the industry, specializing in the production of top-notch solar cables that empower solar energy systems globally.

Unmatched Expertise:

With years of expertise and a commitment to excellence, Xinfeng Cable has become a beacon of innovation in the field of solar cable manufacturing. Our dedicated team of professionals possesses in-depth knowledge of solar cable technology, ensuring that every product we deliver meets and exceeds industry standards.

Premium Quality:

Quality is the cornerstone of our solar cable manufacturing process. We understand that solar cables are the lifeline of solar energy systems, responsible for the efficient and safe transmission of clean power. That’s why each solar cable we produce undergoes rigorous testing and quality assurance protocols to guarantee superior performance and longevity.

Please feel free to contact us: sales@xinfengcable.com