Aerial Bundled Cable Installation

Installation Steps for Aerial Bundled Cable

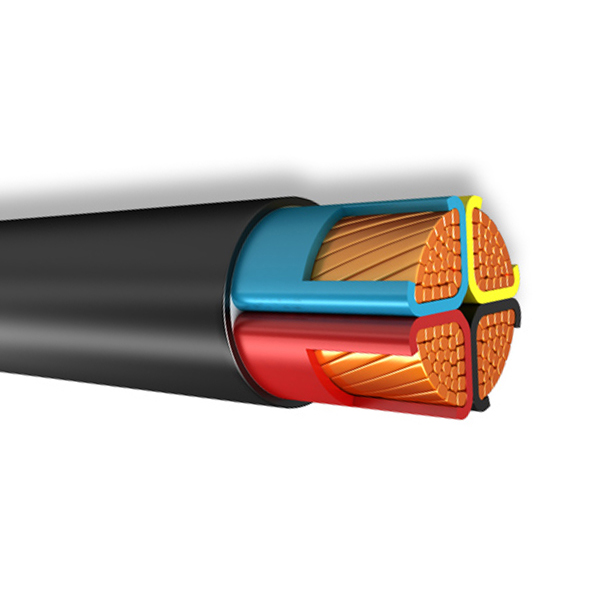

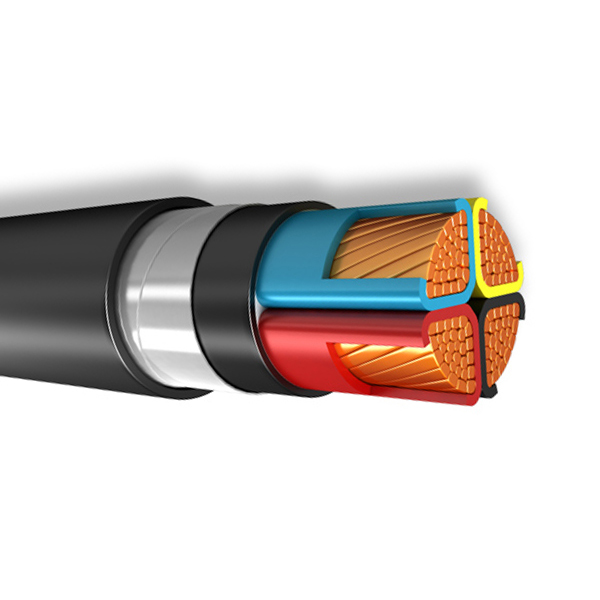

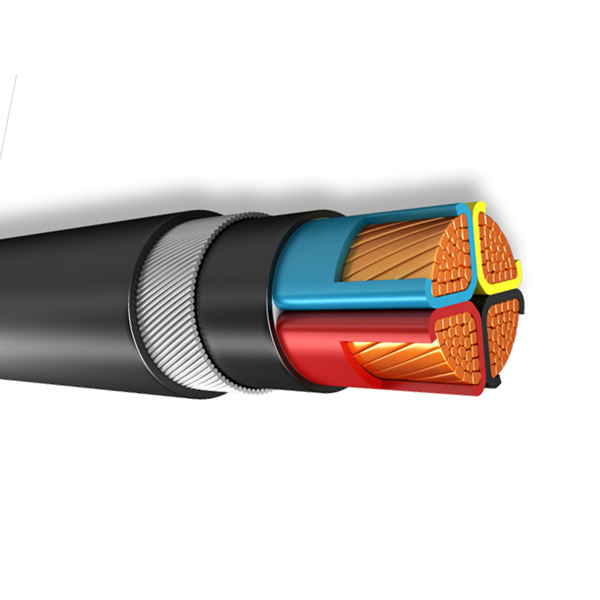

This paper provides an in-depth exploration of the installation steps for Aerial Bundled Cable (ABC Cable), offering a comprehensive guide for professionals in the electrical engineering field. Aerial Bundled Cable has become a preferred choice for overhead power distribution due to its unique design and advantages. The successful installation of Aerial Bundled Cable (ABC Cable) is crucial for ensuring reliable and efficient power transmission. This paper covers each stage of the installation process, from initial planning and site preparation to cable termination and testing. The aim is to equip practitioners with detailed insights, best practices, and considerations for a seamless and effective installation experience.

1. Introduction

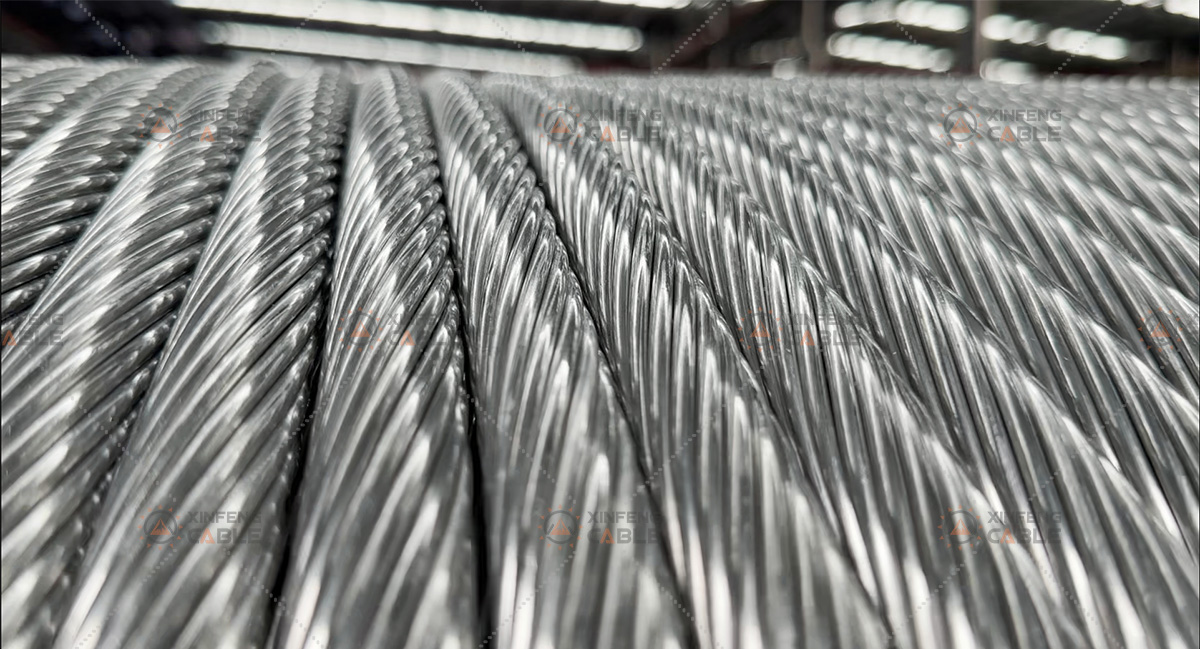

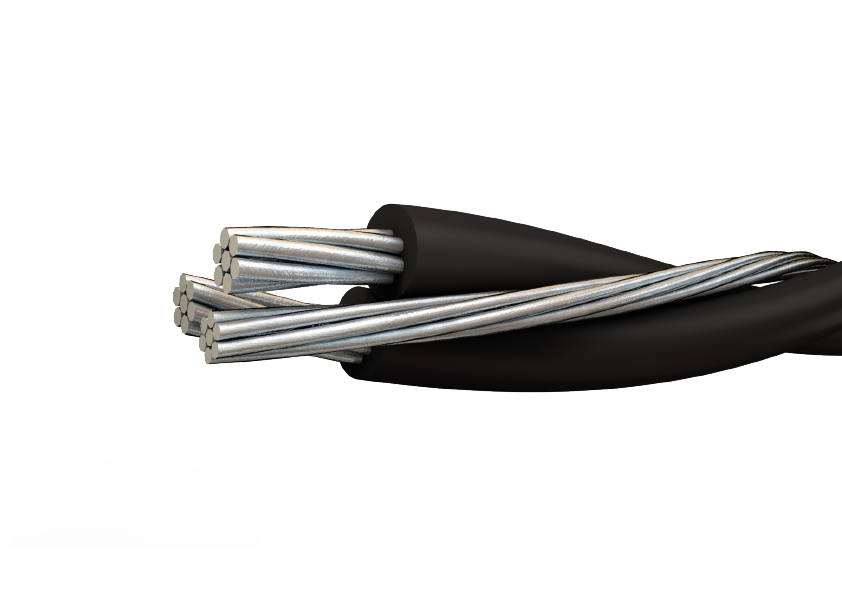

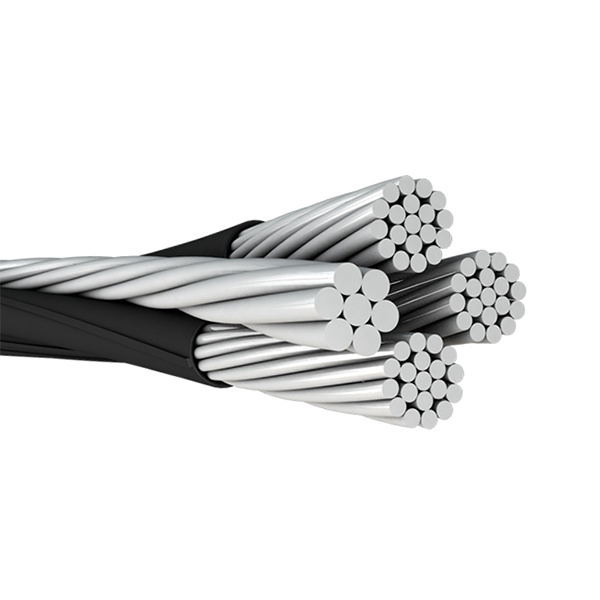

Aerial Bundled Cable (ABC) has gained prominence as a modern solution for overhead power distribution, characterized by bundled conductors encased in a weather-resistant insulation layer.

The installation process plays a pivotal role in determining the performance and longevity of Aerial Bundled Cable systems.

This paper aims to elucidate the step-by-step procedures, emphasizing the intricacies involved in installing Aerial Bundled Cable to meet industry standards and safety protocols.

2. Planning and Site Assessment

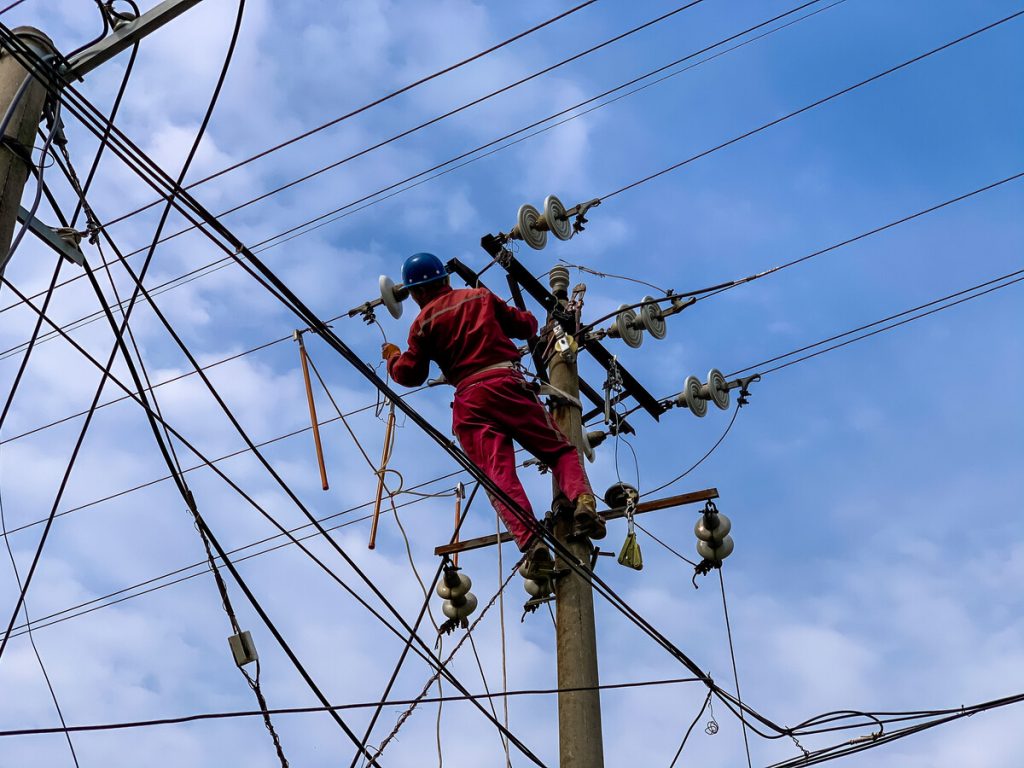

The first phase of Aerial Bundled Cable installation involves meticulous planning and a thorough site assessment. Engineers need to identify the optimal route for cable placement, considering factors such as terrain, potential obstacles, and clearance requirements. A comprehensive survey helps in determining the type and spacing of support structures, minimizing the risk of interference and ensuring the cable’s longevity.

3. Support Structure Selection and Preparation

Selecting suitable support structures is critical to the integrity of the Aerial Bundled Cable system.

4. Cable Routing

Efficient cable routing is essential for minimizing energy losses and preventing mechanical stress on the Aerial Bundled Cable (ABC Cable).

5. Installation of Support Hardware

Proper installation of support hardware, such as clamps, brackets, and insulators, is crucial for securing the Aerial Bundled Cable to support structures.

6. Cable Installation Techniques

Different techniques for installing Aerial Bundled Cable , considering factors such as sag, tension, and conductor spacing. It delves into the use of specialized equipment and tools to facilitate a smooth and precise installation process.

7. Connection and Termination

Connecting the Aerial Bundled Cable to the power source and distribution points requires careful attention to ensure electrical integrity.

8. Sag and Tension Calculations

Maintaining the correct sag and tension in the Aerial Bundled Cable (ABC Cable) is essential for preventing electrical interference and mechanical stress.

9. Testing and Inspection

Thorough testing and inspection are imperative to verify the proper functioning of the installed Aerial Bundled Cable.

10. Safety Measures and Compliance

Safety is paramount during Aerial Bundled Cable installation. Adherence to safety protocols, the use of personal protective equipment (PPE), and compliance with industry regulations and standards to mitigate risks and ensure a secure working environment.

Precautions for Installing Aerial Bundled Cable: Ensuring Safety and Performance

Abstract: This comprehensive paper delves into the crucial aspect of precautions that must be taken during the installation of Aerial Bundled Cable (ABC Cable).

Recognizing the significance of safety, efficiency, and longevity in power distribution systems, this document provides detailed insights into the precautions that engineers, technicians, and installers should consider. By understanding and implementing these precautions, stakeholders can mitigate risks, enhance the reliability of Aerial Bundled Cable systems, and ensure compliance with industry standards.

1. Introduction

The installation of Aerial Bundled Cable (ABC Cable) demands meticulous attention to safety precautions to safeguard both the installation team and the longevity of the system.

This paper focuses on the key precautions that must be observed throughout the installation process to prevent accidents, ensure optimal performance, and comply with regulatory requirements.

2. Risk Assessment and Hazard Identification

Before initiating the installation, a comprehensive risk assessment and hazard identification process are essential.

3. Adherence to Safety Standards and Regulations

Ensuring compliance with safety standards and regulations is paramount.

4. Personal Protective Equipment (PPE)

The proper use of Personal Protective Equipment (PPE) is a fundamental precaution during Aerial Bundled Cable (ABC Cable) installation.

5. Environmental Considerations

The impact of environmental factors on the installation process. Considerations for varying weather conditions, terrain, and potential ecological concerns are highlighted, along with recommendations for adapting installation practices accordingly.

6. Tools and Equipment Safety

The safe use and maintenance of tools and equipment are integral to a secure installation process. The selection of tools, their calibration, and guidelines for their proper use to prevent accidents and equipment malfunction.

7. Electrical Safety Measures

Aerial Bundled Cable installations involve working with electrical components, necessitating specific precautions to prevent electrical accidents.

Such as de-energizing lines, lockout/tagout procedures, and guidelines for working near energized conductors.

8. Cable Handling and Transportation

Proper handling and transportation of Aerial Bundled Cable reels are crucial for preventing damage to the cable and ensuring installer safety. Cable storage, loading, unloading, and transportation, emphasizing the need for careful handling to avoid twists, kinks, or other potential issues.

9. Emergency Response Planning

Despite all precautions, unforeseen emergencies can occur. It`s import to have a well-defined emergency response plan, including first aid measures, communication protocols, and evacuation procedures.

10. Training and Continuous Education

The significance of ongoing training and education for installation teams. Regular updates on safety protocols, technological advancements, and industry best practices are vital to maintaining a culture of safety within the installation workforce.

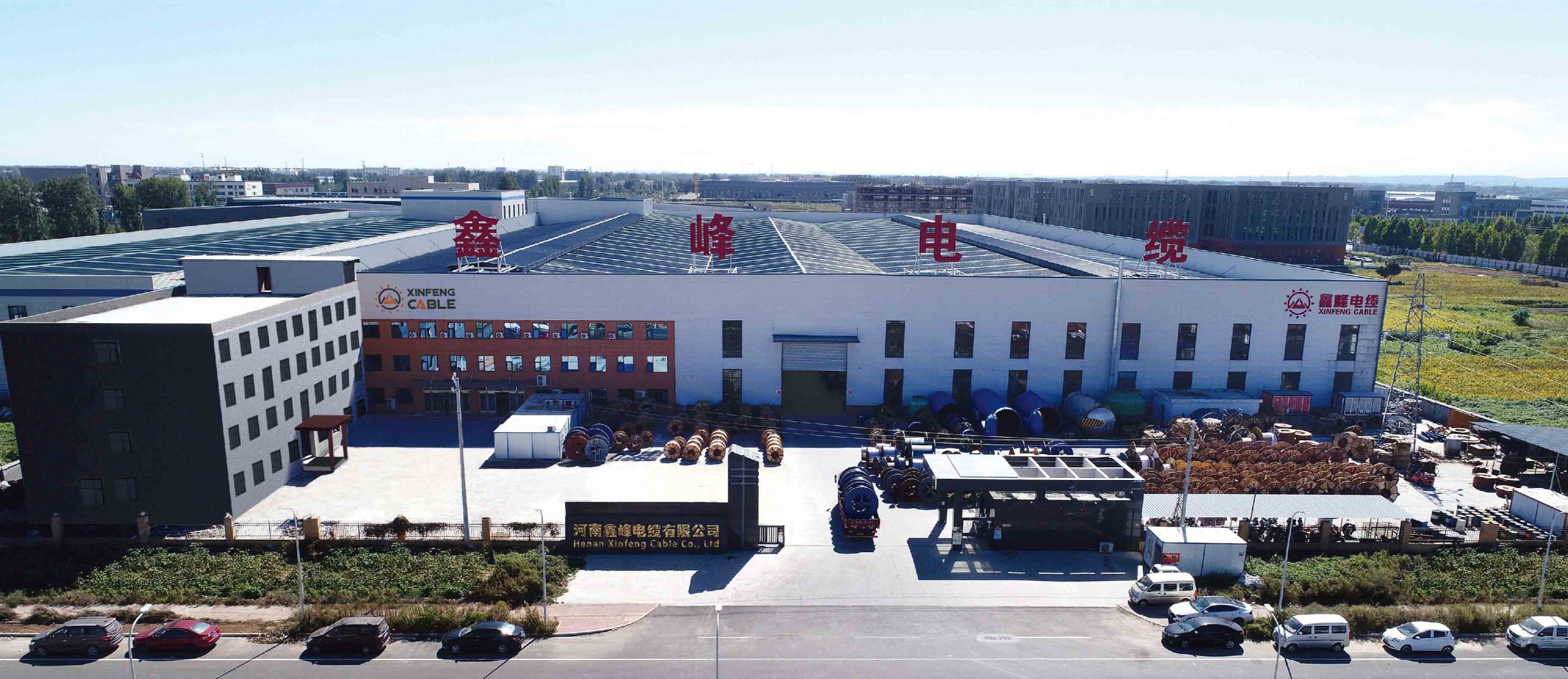

Xinfeng Cable is a premier cable manufacturer, exemplifying excellence in the industry. Committed to innovation, quality, and customer satisfaction, we have become a trusted name in cable manufacturing.

Our dedication to quality is unparalleled. Each cable undergoes rigorous testing, ensuring it not only meets but often exceeds international standards. This commitment ensures our products provide reliable and durable solutions across various applications.

Customer satisfaction is paramount. Recognizing the unique requirements of each project, our customer-centric approach allows us to tailor products to specific needs. Our responsive support team ensures a seamless experience from inquiry to post-installation.

As a global player, we embrace diversity and inclusivity. Our international team fosters a culture of collaboration and creativity, enabling us to approach challenges from multiple perspectives.

- 5/F, Building 5, New Development Kinner Smart Plaza, Zhengzhou City, China

- No.9, Wuqiao Road, Qiaomiao Town, Wuzhi County,Jiaozuo City,China

- +86 371 6505 3833

- + 86 1 3333 8683 99

- sales@xinfengcable.com