What are High Voltage Cables Made of?

High voltage cables serve as critical conduits for the efficient transmission of electrical power over extended distances. This article delves into the intricate structure of high voltage cables, dissecting each component to unveil the synergy that enables their reliable and safe operation.

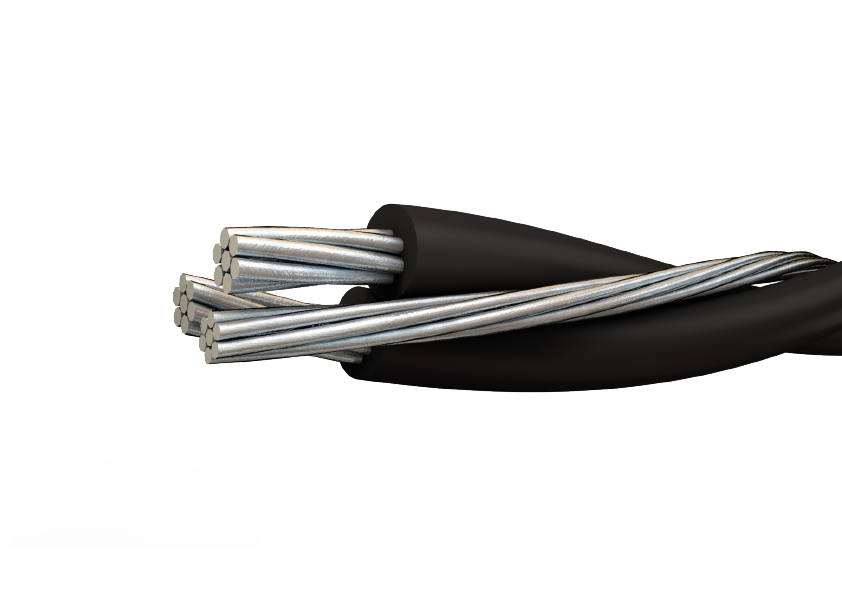

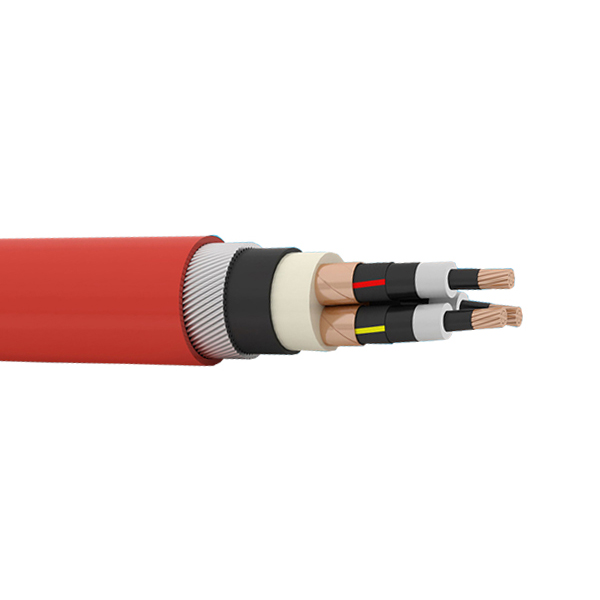

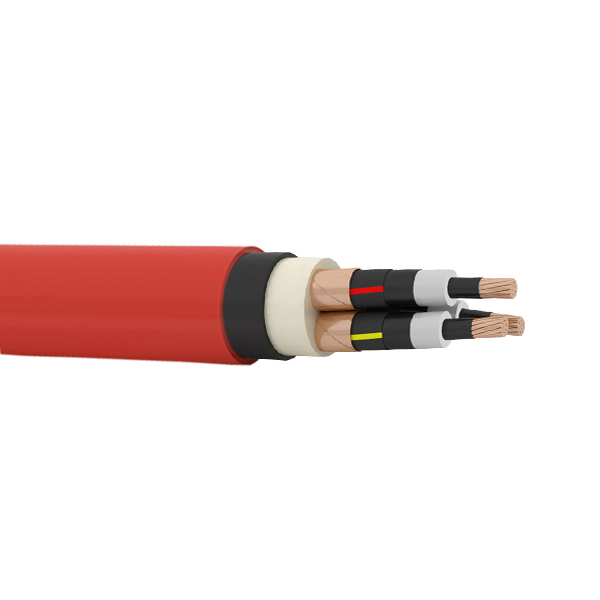

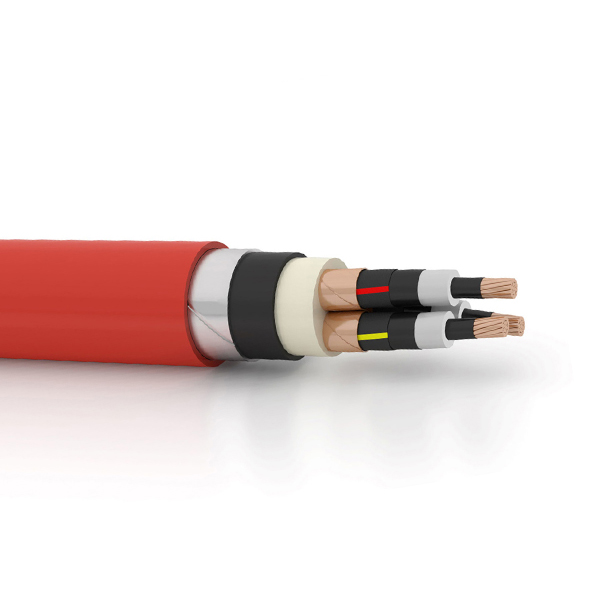

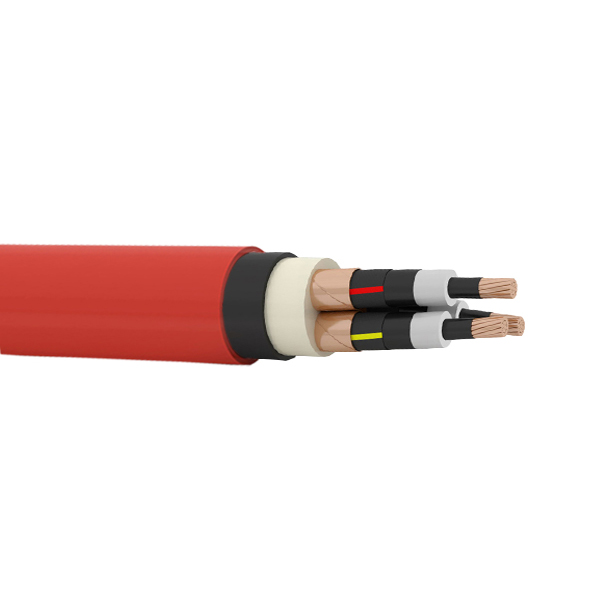

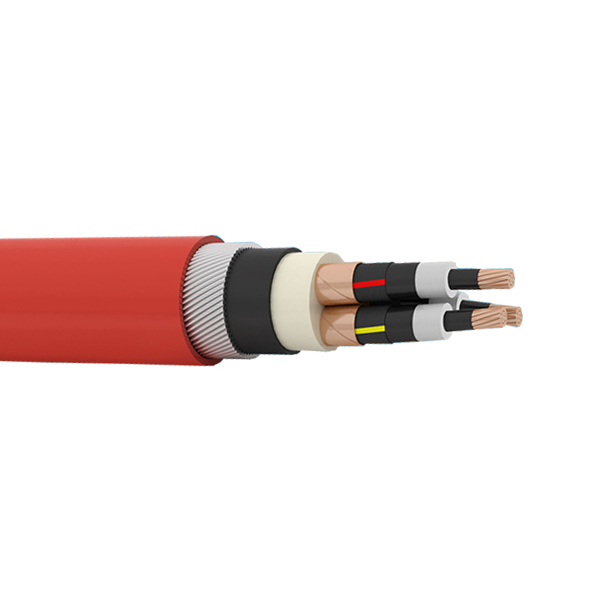

1. Conductors: High voltage cables commence with the conductors, typically crafted from copper or aluminum. Renowned for their excellent conductivity, these materials ensure minimal power loss during transmission. The choice between copper and aluminum hinges on factors such as cost and weight considerations.

2. Insulation: Insulation acts as a protective barrier against electrical leakage. Common insulation materials include Cross-Linked Polyethylene (XLPE) and Ethylene Propylene Rubber (EPR). XLPE, known for its thermal stability, and EPR, prized for flexibility, both provide robust insulation to withstand high voltages.

3. Semiconductive Layers: Semi-conductive layers encase the insulation, ensuring a uniform distribution of electrical stress. Composed of conductive polymers or tapes, these layers mitigate the risk of partial discharges, enhancing the overall reliability of the cable.

4. Metallic Shield: Surrounding the insulation, the metallic shield, often made of copper or aluminum tapes, shields the cable from external electromagnetic interference. It also contains the electric field within, preventing potential disruptions to surrounding equipment.

5. Insulation Screen: Positioned between the insulation and metallic shield, the insulation screen consists of conductive materials like semiconducting tapes. It contributes to the cable’s capacitance properties and provides a smooth surface, ensuring optimal electrical performance.

6. Fillers and Binder Tapes: Fillers and binder tapes serve to maintain the cable’s shape and provide additional insulation. Typically crafted from non-conductive materials like paper or synthetic tapes, these components contribute to the cable’s mechanical integrity.

7. Outer Sheath: The outer sheath serves as the final layer, safeguarding the cable against mechanical damage, moisture, and environmental factors. Common materials for outer sheaths include Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE).

8. Armor (Optional): In scenarios demanding heightened mechanical protection, high voltage cables may feature an optional armored layer. Steel wires or tapes are commonly used for this purpose, ensuring durability in challenging environments.

History of High Voltage Cables

The concept of high voltage cables took root in the late 19th and early 20th centuries. With the rise of alternating current (AC) power systems championed by Nikola Tesla, there emerged a need for cables capable of efficiently transmitting electricity over long distances. The first high voltage cables were developed to address this demand, enabling the expansion of power distribution networks. High voltage cables revolutionized power transmission by allowing electricity to be transported over significant distances with minimal loss. This innovation addressed challenges associated with the efficient distribution of electrical energy, particularly in urban and industrial settings.

In the mid-20th century, advancements in insulation materials, such as oil-impregnated paper and later synthetic materials like Cross-Linked Polyethylene (XLPE) and Ethylene Propylene Rubber (EPR), improved the performance and reliability of high voltage cables. These innovations expanded their applications in various industries, including power generation, distribution, and industrial processes.

In recent decades, high voltage cables have become indispensable components of modern power grids and industrial systems. Their applications include:

- Interconnected Power Grids: High voltage cables facilitate the interconnection of regional and national power grids, ensuring reliable electricity supply.

- Renewable Energy Integration: With the growing emphasis on renewable energy sources, high voltage cables play a crucial role in transmitting power from remote renewable energy sites (such as wind farms and solar installations) to population centers.

- Electric Transportation: High voltage cables are integral to electric transportation infrastructure, supporting the charging and distribution of power for electric vehicles.

As technology continues to advance, the future of high voltage cables holds exciting possibilities:

- Smart Grid Integration: High voltage cables are expected to play a key role in evolving smart grid systems, enabling real-time monitoring, control, and optimization of power distribution.

- Enhanced Materials and Efficiency: Ongoing research focuses on developing advanced materials to enhance the efficiency and environmental sustainability of high voltage cables.

- Integration with Energy Storage: High voltage cables may find new applications in conjunction with energy storage systems, contributing to grid stability and resilience.

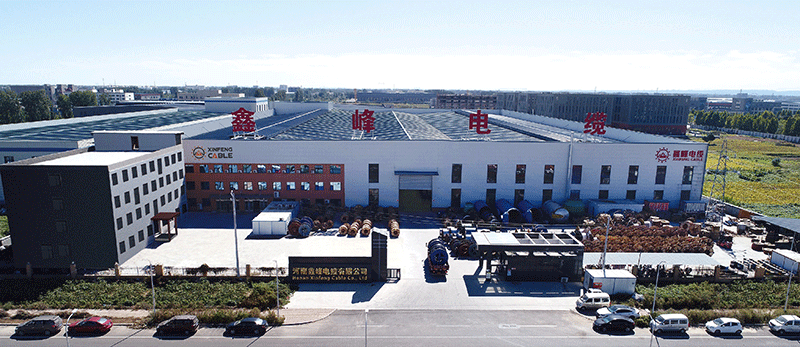

Xinfeng Cable: Your Premier Cable Manufacturing Partner

Xinfeng Cable stands as a dedicated and customer-centric cable manufacturer, specializing in the production of high-quality cables. With a commitment to excellence, we cater to a global clientele, ensuring top-notch service and reliable products.

Welcome to contact Xinfeng Cable

- 5/F, Building 5, New Development Kinner Smart Plaza, Zhengzhou City, China

- No.9, Wuqiao Road, Qiaomiao Town, Wuzhi County,Jiaozuo City,China

- +86 371 6505 3833

- + 86 1 3333 8683 99

- sales@xinfengcable.com